Induction heating, melting, hardening and specialised equipment

Our partner is a leading developer and supplier of induction heating, melting, hardening and specialised equipment on the Indian and international markets. The company began its journey in 2012 with more than 120 qualified team members and has positioned itself as a manufacturer of high-quality and precise induction equipment. TCT Tesic is the official distribution partner on the European market and will assist its customers and partners in all sales and communication processes.

Technological expertise and quality promise

The manufacturer attaches great importance to precision, energy efficiency and customer-specific solutions. The systems are characterised by very high reliability, durability and process stability. They are developed and manufactured with the support of a team of over 120 engineers, technicians and skilled workers. This technological background forms the basis for high customer satisfaction – according to the company’s own figures, the rate is almost 98%.

The focus is on developing efficient systems that are precisely tailored to the needs of customers – from medium-sized companies to large industries with high requirements in terms of production output and automation.

More information about our partner Plasma Plasma Induction Pvt. Ltd. can be found here:

Product portfolio at a glance

The range is divided into four main areas:

- Induction heating system:

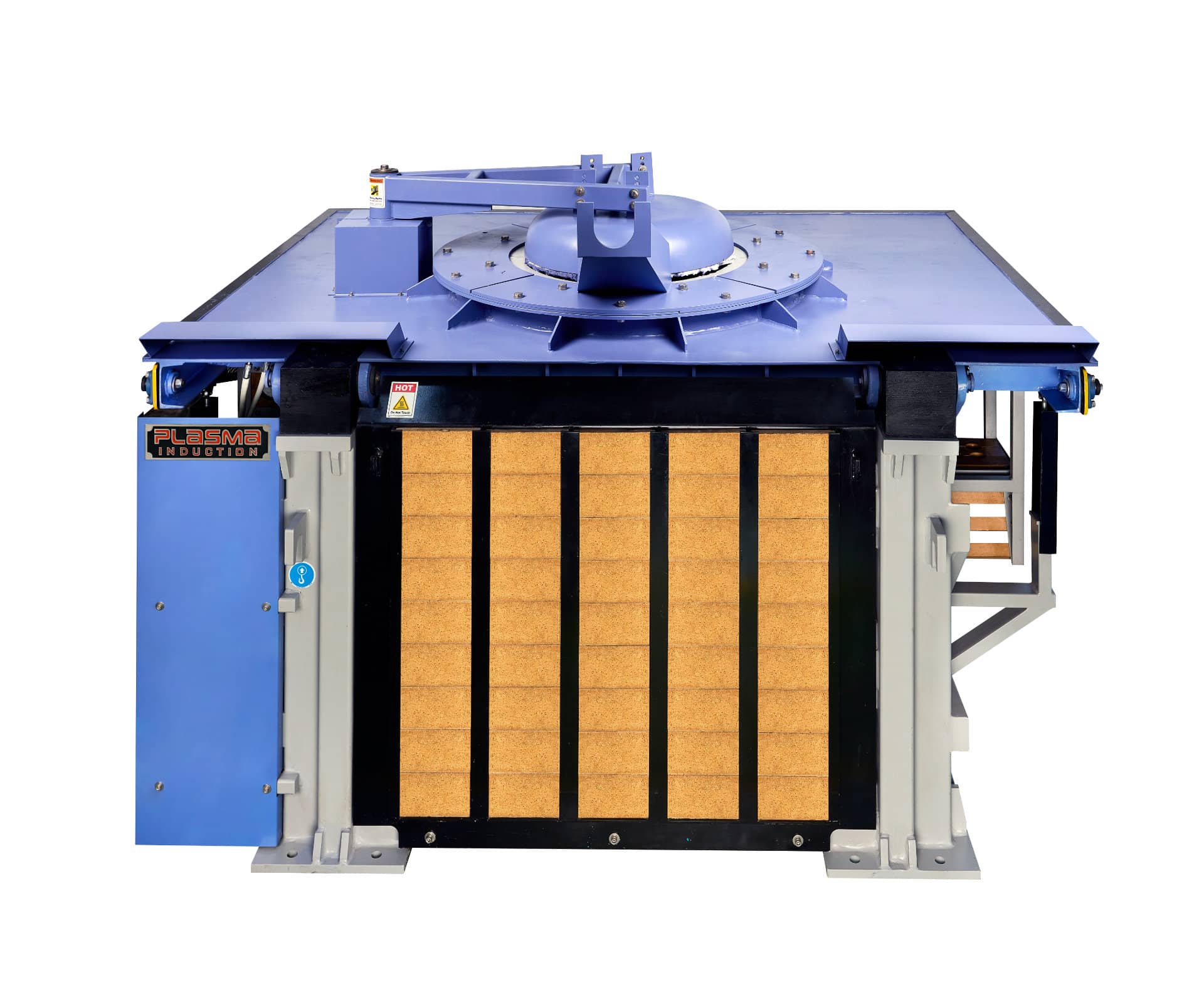

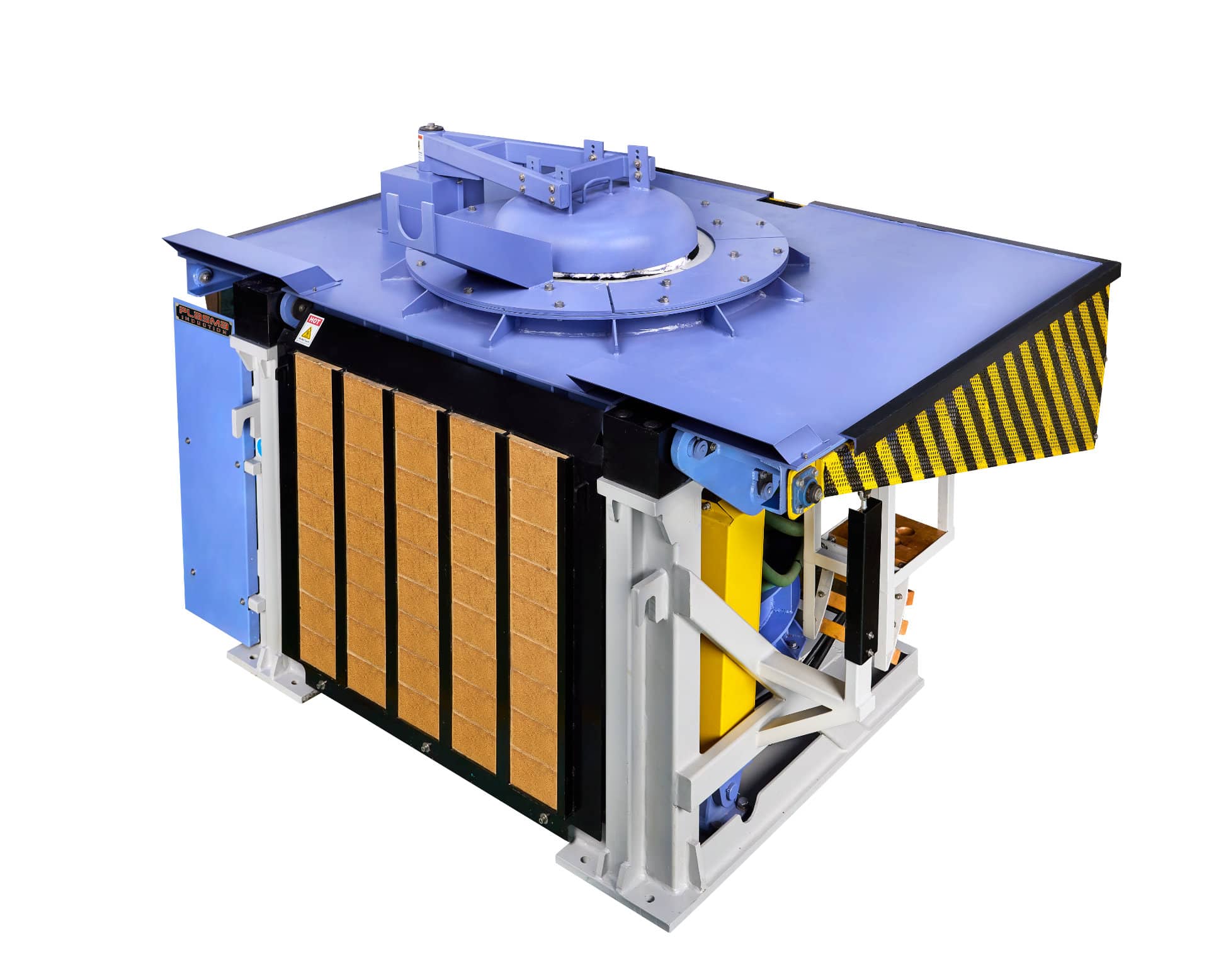

These systems are used to heat metals, for example before forging or forming. Precisely controllable heating processes allow quality, energy consumption and production speed to be optimally coordinated. - Induction melting system:

These systems are used in particular in foundries and are designed for the precise, fast and clean melting of ferrous and non-ferrous metals. The induction technologies used enable high energy efficiency combined with precise temperature control. - Induction hardening systems:

These enable targeted hardening processes on defined areas of a workpiece, improving mechanical properties such as wear resistance and service life. These systems are used in the automotive and mechanical engineering industries, among others. - Special systems and customised solutions:

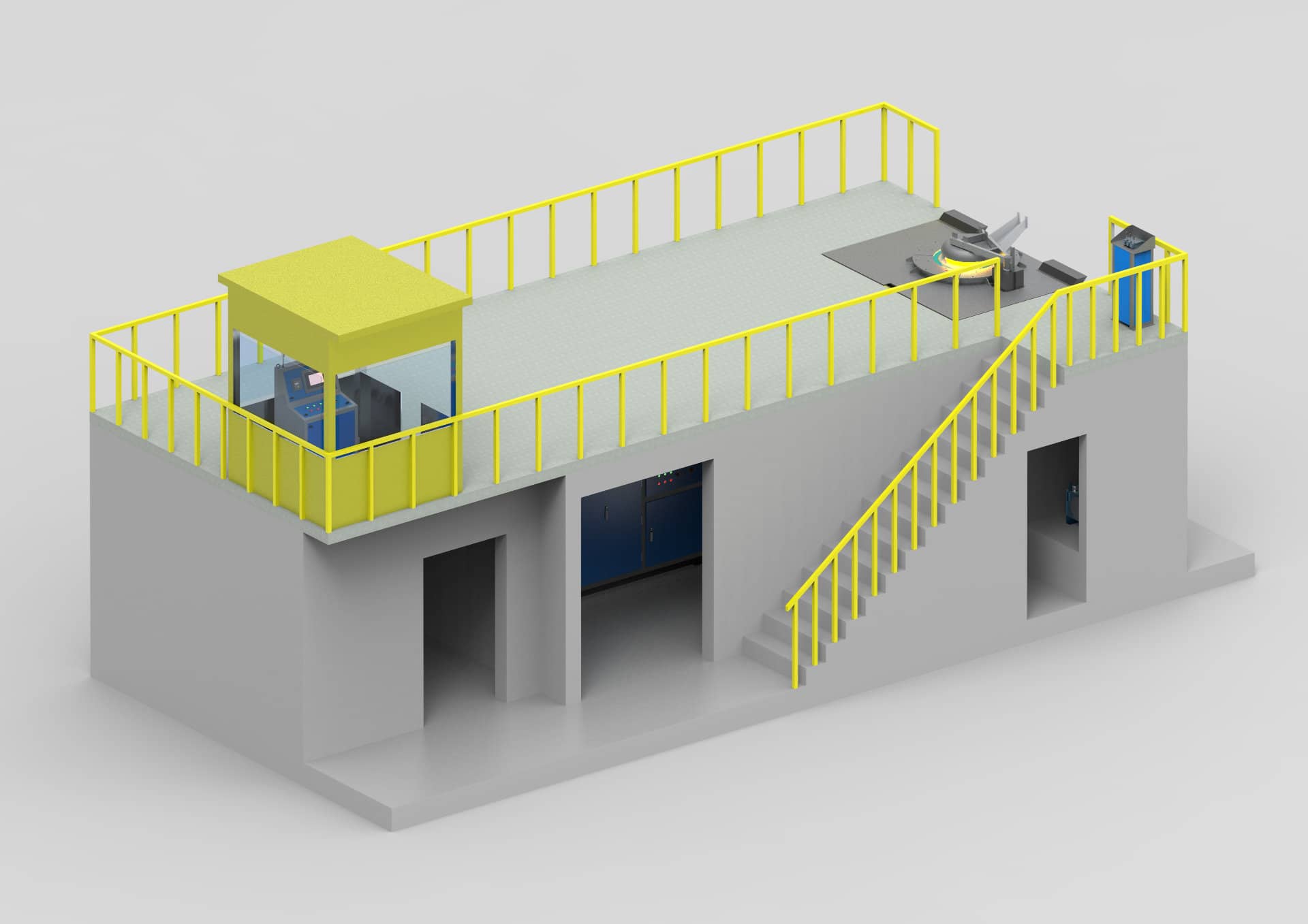

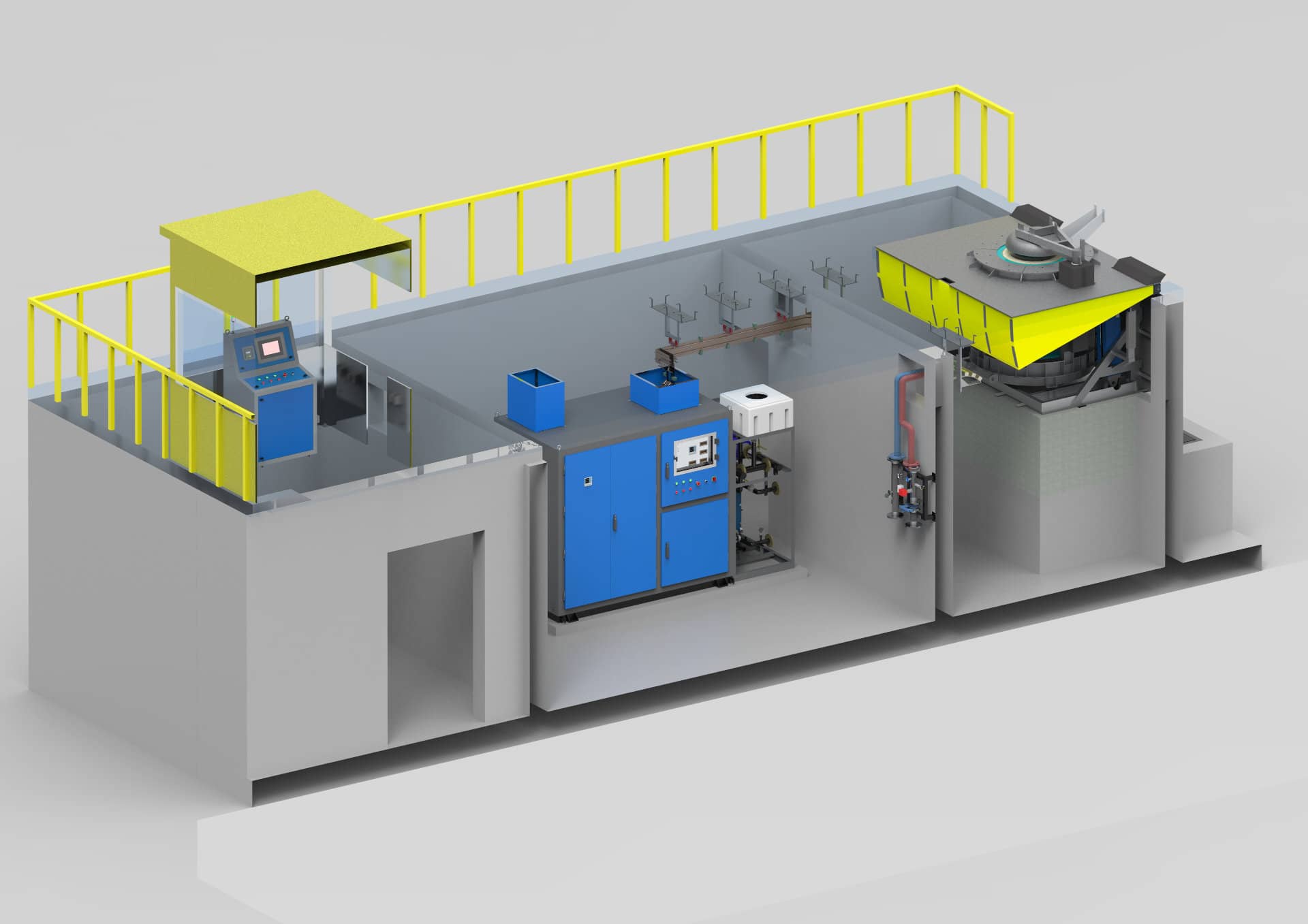

Special solutions are developed on customer request, tailored to specific processes or spatial conditions. These include combinations of melting, casting and transport functions as well as automated complete systems.

One of Metal Power’s particular strengths is its consistent use of modern CMOS/CCD detector technology, which surpasses older PMT systems in terms of flexibility, compactness, cost efficiency and performance.

More information about the products is available here:

Technical features and highlights

The company offers a wide range of high-performance spectrometers adjusted to a variety of requirements:

Boiler sizes and furnace volumes

Various capacities are available for melting plants, ranging from small laboratory furnaces to large-scale plants for industrial series production.

Performance ranges

Systems are available in different performance classes – adapted to specific requirements in terms of production volume and material type.

Construction

Robust construction with high-quality insulation, user-friendly interfaces and maintenance-friendly access points.

Control technology

Use of modern PLC and HMI systems for easy control, monitoring and documentation of all process parameters.

Energy efficiency

The systems are designed to minimise power consumption and energy losses – a key consideration given today’s production costs and sustainability targets.

Safety features

All systems are equipped with modern protection systems such as temperature monitoring, emergency shutdown, pressure sensors and automatic fault diagnosis.

In addition, Metavision-RX, an RDE spectrometer, provides accurate oil analysis for industries such as aviation, shipping, automotive and power generation.

Customer focus and customised solutions

A key feature of the offering is the high degree of flexibility in developing customised solutions. Customers can choose from a wide range of modules and equipment options or receive a fully customised solution that is precisely tailored to their specific production conditions. This makes the systems particularly attractive for companies with specific requirements or special structural specifications.

Service and distribution by TCT Tesic

TCT Tesic handles all sales and communication tasks for the European market. This includes:

- Technical advice on selecting suitable equipment

- Project support from planning to commissioning

- Communication between end customers and manufacturers

- Coordination of after-sales services, maintenance and training

Thanks to its many years of experience in the foundry equipment market, TCT Tesic acts as a competent interface that not only knows the technical side, but also understands the requirements of European customers and implements them reliably.

The cooperation between TCT Tesic and the manufacturer of induction systems gives European customers access to modern, powerful and energy-efficient technologies in the field of metal processing. The systems are suitable for a wide range of applications – from metalworking and foundries to industrial-scale heat treatment.

With comprehensive expertise, customisable systems and trustworthy customer service, TCT Tesic offers an ideal solution for companies that value quality and innovation in the field of induction technology.

Newsletter & Machine service

Whether you want to buy a used machine or have a machine to sell, we are here to help and advise you.

- Subscribe to our newsletter: Stay up to date with new machine offers and exclusive promotions. Don’t miss out on any opportunities and sign up now.

- Request a machine: Have you seen a suitable machine or do you have specific requirements? Submit your machine request today. We will find the optimal solution for you and get back to you as soon as possible.

- Sell machine: Do you own a core shooting machine that you would like to sell? You’ve come to the right place. Contact us and we will help you sell your core shooting machine – quickly, reliably, and at the best possible price.

TCT Tesic – your partner for comprehensive foundry services. We look forward to your inquiry!

If you have any further questions, please do not hesitate to contact us or use our contact form.