Used blasting systems for foundries

Used blasting systems are indispensable in foundries for cleaning castings after casting and preparing them for further processing. This type of system is used to remove adhesions such as burrs, sharp edges and sand residues from castings – for clean surfaces and precise end products. Blasting systems are used in particular after the moulding process (the demoulding of the cast workpieces) to efficiently remove any remaining moulding sand and scale. TCT Tesic offers a comprehensive range of blasting systems for foundries – from used overhead conveyor blasting systems to used continuous blasting systems. Benefit from our expertise if you want to buy a used blasting system or sell your existing blasting system.

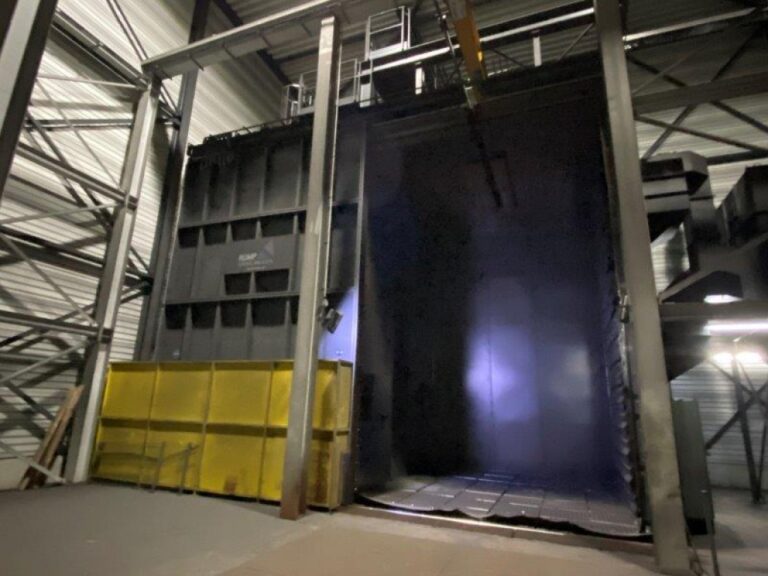

Blasting systems

- Position: 101451

- Brand: RUMP

- Model: CAPSOR 40 13-U-S

- Year: 2016

- Capacity: 246 kW

- Type: Fettling shops, Fettling shops

Mainly consists of: Hanger type Shotblaster: Blasting chamber – internal dimensions LxWxH: 6 x 5 x 7.5 m, grape dimensions: diameter – 4 m x height 6 m, hook height: 7,05 m Floor grids Bucket

- Position: A13-1.7

- Brand: RUMP

- Model: 20-D-1250

- Year: 1995

- Capacity: 6,0 m/s

- Type: Fettling shops, Fettling shops

Mainly consists of: Shot blast chamber: LxWxH: 4700x 1800x 2850 mm 8 nos. Turbo blast wheels Typ TSM IV / Connected load: 15/12 KW Bucket elevator Longit. Screw conveyor Transport wire belt Width: 1250 mm

- Position: A13-1.8

- Brand: RÖSLER

- Model: RHBD 15/20 - T

- Year: 2008

- Type: Fettling shops, Fettling shops

Mainly consists of: Blasting chamber with double doors Monorail steel construction with turning devices and hooks Abrasive bucket elevator Screw conveyor Control and operating cabinet with SIEMENS PLC S7 Number of blast wheels: 4 Total

- Position: A13-1.9

- Brand: DISA Wheelabrator

- Model: ML-12/0518-202

- Year: 2003 (Umbau)

- Capacity: 272 kg

- Type: Fettling shops, Fettling shops

Mainly consist of: Blasting chamber with double doors Monorail steel construction with hooks and transport chain Blasting media bucket elevator Screw conveyor Control and operating cabinet with PLC controls Number of blast wheels 12 Drive

Successfully installed blasting systems

TCT Tesic has already successfully brokered numerous blasting systems. You can find an extract from our references in the following table:

- Wheelabrator HTS-4 overhead conveyor blast machine – sold to the automotive industry in Germany.

- DISA/Wheelabrator CT6 continuous blast machine – sold to a steel foundry in Poland.

- Rump RDGE-3 troughed belt blast machine – sold for agricultural machinery production in Italy.

- Pangborn continuous flow system – sold to the mechanical-engineering sector in Russia.

- Vogel & Schemann overhead conveyor blast machine (older model) – sold to a foundry in Spain.

Note: This is only a selection of successfully brokered machines. We will be happy to provide you with further references and details on request.

Blasting system manufacturers & models of blasting systems

The following manufacturers and model series are particularly in demand in the field of blasting technology for foundries:

Wheelabrator

Overhead conveyor blast machines (HTS series), continuous blast machines (CT series)

DISA

Blasting systems from the Norican Group (identical in construction to Wheelabrator)

Rump

Rump blasting systems: continuous and overhead conveyor blasting systems (various types, e.g. RH, RD series)

Vogel & Schemann

Older overhead conveyor blast machines for heavy castings

Handte

Blasting systems with integrated extraction technology

Pangborn

Continuous throughfeed blasting systems (for series production)

Schlick

Special blasting systems and components

Gutmann

Foundry blasting systems (various types)

If your preferred manufacturer or a specific model is not currently available, take advantage of our international network: We can procure the blasting systems you are looking for for you worldwide.

Related categories

Many processes are interlinked in foundry technology. A grinding process often follows directly after blasting – TCT Tesic therefore also offers used grinding systems for the post-processing of cast parts. In addition, we cover the entire foundry process chain with used machines, from core shooters to moulding plants, melting furnaces, sand preparation plants and dedusting plants through to manipulators. Please feel free to browse through these categories to find all the equipment relevant to your production.

FAQ

A shot blasting machine is a machine for cleaning the surfaces of metal parts. Blasting systems are used in foundries to remove sand, scale (oxide layers) and small burrs from cast parts after demoulding. Blasting gives the workpieces a clean surface for further processing or quality inspection. In short, blasting systems are used to deburr, desand and clean cast surfaces using accelerated blasting media (e.g. steel balls).

A distinction is mainly made between overhead conveyor blast machines and throughfeed blast machines. In overhead conveyor systems, the parts hang on hooks and are blasted in batches – ideal for large, heavy or complex workpieces. Continuous feed systems feed the parts continuously through the blast cabinet, for example on roller conveyors or in troughed belts, which is suitable for large quantities and series production. There are also special designs (e.g. barrel blasting systems for small bulk parts), but the focus is on overhead conveyors and through-feed systems, as they cover most foundry requirements.

If you want to buy a used blasting system, you should pay attention to several points: The technical condition (blast machine maintenance) of the machine is crucial – check wear parts such as blast wheels, inner panelling of the blast chamber and filter elements of the dust extraction system. The control technology (electrics/electronics) should also be functional and as up-to-date as possible. It is also important that spare parts are available for the manufacturer and model in question. Finally, the size and performance data of the system play a role: Make sure that the capacity (e.g. maximum workpiece dimensions, batch weight) and the throughput rate (e.g. tonnes/hour of blasting media circulation) match your requirements. If in doubt, TCT Tesic will support you in the evaluation and selection of suitable used blasting systems.

If you would like to sell a blasting machine, TCT Tesic is the right contact. We will add your machine to our portfolio and take care of marketing it in our international network. Firstly, the current condition of the machine is recorded (technical details, pictures, history). We then search specifically for buyers for whom your machine is suitable – e.g. foundries that favour precisely this capacity or manufacturer. We coordinate viewing appointments, negotiate the conditions if there is interest and accompany the sales process through to safe dismantling and collection. Thanks to our experience, you will achieve a fair market price and a swift, professional transaction.

No, our focus is on blasting systems for foundries with blast wheel technology (i.e. shot blasting systems). Sandblasting systems (compressed air-operated blasters) or dry ice cleaning systems are not part of our speciality, as they are rarely used in foundries. However, if you are looking for a solution for cleaning your workpieces, we will be happy to advise you on which blasting process is best suited to your application – although our focus is on classic used foundry blasting systems and their accessories, such as blasting system extraction. In addition, we also offer you a blasting system service.

Several manufacturers of blasting systems have proven themselves in foundries over the years. Systems from Wheelabrator and DISA (today often under the joint Norican group, known for robust and powerful technology) are very common. German manufacturers such as Rump or the long-established company Vogel & Schemann are also frequently found in foundries. Other well-known manufacturers include Pangborn, Schlick, Gutmann and Rösler blasting systems. Each brand has its own specialities – if required, we will be happy to explain the differences and advantages of the individual models, e.g. of automatic blasting systems, so that you can make the right choice for your production

About TCT Tesic

TCT Tesic is your competent partner when it comes to used foundry machines – naturally also in the field of blasting systems. As an internationally active company specialising in the foundry industry, we bring buyers and sellers of used equipment together. Decades of industry experience and technical expertise enable us to provide you with comprehensive advice, find the right solution for your requirements and ensure a smooth transaction. Our range of services extends from the evaluation and inspection of used blasting systems to marketing in a global network and the organisation of dismantling, transport and recommissioning. At TCT Tesic, your production goals take centre stage – we find the machine that suits you or support you in successfully selling your system. Put your trust in a partner who speaks the language of foundry technology and is passionate about giving used machines a new lease of life in another foundry.

Design & function of a blasting system

Blasting technology in foundries: Blasting systems (also known as wheel blasting systems) are robust machines that are specially designed for cleaning metal castings. At their heart are rotating blast wheels (turbines) that throw metallic blasting media – usually steel balls or grit – onto the workpiece surface at high speed. This mechanically removes adhering moulding sand, casting residues and scale. The cleaned cast parts leave the system with a roughened surface free of residues, which is ideal for subsequent processes such as grinding or coating.

Types of shot blasting systems: There are two main types of shot blasting systems for foundries – overhead and continuous shot blasting systems. In overhead conveyor blast machines, the workpieces are suspended from hooks or cross beams. They move past the blast wheels in a blast chamber or rotate in it so that all sides of the workpiece are blasted. This process is particularly suitable for larger, heavy parts (individual weight typically 100-500 kg) and irregularly shaped castings. Continuous shot blasting systems, on the other hand, transport the parts continuously through the system – e.. on a roller conveyor, a conveyor belt or in a troughed belt tunnel. Such systems (such as the CT3 to CT6 series) are ideal for large quantities and series production, as they work without interruption. Small to medium-sized workpieces can be blasted efficiently in large numbers.

Performance & equipment: The performance parameters of a blasting system depend on the size and application. Standard systems have several blast wheels with a total installed drive power of approx. 15-200 kW. This achieves abrasive throughputs of around 5-20 tonnes per hour – a measure of the machine’s cleaning performance. A typical system consists of a closed blast chamber with a wear-resistant inner lining, the blast wheel turbines, a conveyor system for the workpieces (overhead conveyor, roller conveyor, etc.) and a reconditioning system for the blast media. The latter includes screw conveyors, elevators, separators and bunkers to collect the used abrasive, separate it from dust and debris and reuse it. Last but not least, a powerful dedusting system is integrated or connected, which extracts the fine dust and removed particles. This ensures visibility in the process and clean exhaust air, which protects both the working environment and the environment.

Newsletter & Machine service

Whether you want to buy a used machine or have a machine to sell, we are here to help and advise you.

- Subscribe to our newsletter: Stay up to date with new machine offers and exclusive promotions. Don’t miss out on any opportunities and sign up now.

- Request a machine: Have you seen a suitable machine or do you have specific requirements? Submit your machine request today. We will find the optimal solution for you and get back to you as soon as possible.

- Sell machine: Do you own a core shooting machine that you would like to sell? You’ve come to the right place. Contact us and we will help you sell your core shooting machine – quickly, reliably, and at the best possible price.

TCT Tesic – your partner for comprehensive foundry services. We look forward to your inquiry!

If you have any further questions, please do not hesitate to contact us or use our contact form.