Used grinding systems for foundries

Used grinding systems are an essential part of post-processing in foundries. After blasting, castings are often deburred, ground or prepared for further processing. TCT Tesic supplies robust, industrially proven grinding systems specifically for the casting sector – e.. for grey cast iron, steel or cast aluminium. Whether automatic grinding cells, hand-guided grinding machines or specialised deburring systems: Here you will find the right used grinding system for your requirements.

Use our international network if you want to buy or sell a used grinding machine. Our team will support you from technical advice to dismantling and commissioning the machine at your site.

Grinding systems

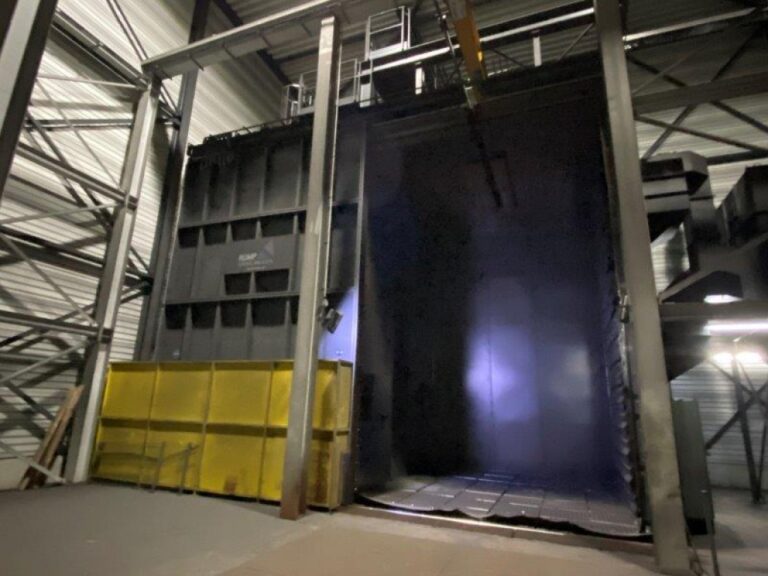

- Position: 101451

- Brand: RUMP

- Model: CAPSOR 40 13-U-S

- Year: 2016

- Capacity: 246 kW

- Type: Fettling shops, Fettling shops

Mainly consists of: Hanger type Shotblaster: Blasting chamber – internal dimensions LxWxH: 6 x 5 x 7.5 m, grape dimensions: diameter – 4 m x height 6 m, hook height: 7,05 m Floor grids Bucket

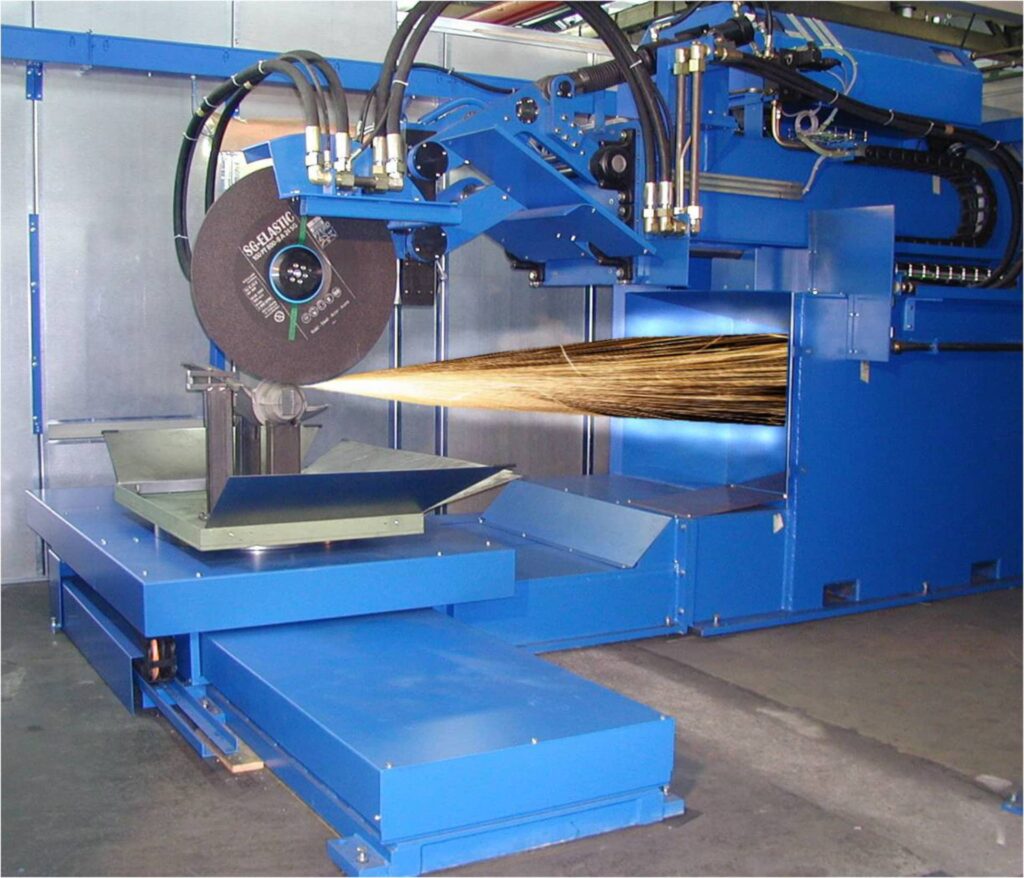

- Position: 101575

- Brand: MAUS s.r.l. Italien

- Model: SAM 300G

- Year: 2020 (WIE NEU)

- Capacity: Max. 40 kg

- Type: Fettling shops, Fettling shops

Max. part weight: 40 kg Max. part height: 290 mm Max. part swing: 450 mm Mainly consists of: Complete Grinding cell Automatic Pallet Changer Part Measuring Laser System The machine is NEW and was not

- Position: A13-1.7

- Brand: RUMP

- Model: 20-D-1250

- Year: 1995

- Capacity: 6,0 m/s

- Type: Fettling shops, Fettling shops

Mainly consists of: Shot blast chamber: LxWxH: 4700x 1800x 2850 mm 8 nos. Turbo blast wheels Typ TSM IV / Connected load: 15/12 KW Bucket elevator Longit. Screw conveyor Transport wire belt Width: 1250 mm

- Position: A13-1.8

- Brand: RÖSLER

- Model: RHBD 15/20 - T

- Year: 2008

- Type: Fettling shops, Fettling shops

Mainly consists of: Blasting chamber with double doors Monorail steel construction with turning devices and hooks Abrasive bucket elevator Screw conveyor Control and operating cabinet with SIEMENS PLC S7 Number of blast wheels: 4 Total

- Position: A13-1.9

- Brand: DISA Wheelabrator

- Model: ML-12/0518-202

- Year: 2003 (Umbau)

- Capacity: 272 kg

- Type: Fettling shops, Fettling shops

Mainly consist of: Blasting chamber with double doors Monorail steel construction with hooks and transport chain Blasting media bucket elevator Screw conveyor Control and operating cabinet with PLC controls Number of blast wheels 12 Drive

- Position: A11-04

- Brand: EURO-EQUIP

- Model: AP 900-50

- Year: 2015

- Capacity: 5 - 8 t/h

- Type: Fettling shops, Fettling shops

Mainly consists of: Main body of the crusher Hydraulic unit Electric cabinet Hopper – inkl. Protection and support structure Skip loader and its support structure Vibrating conveyor 900 x 3500 mm As seen, ex works,

Successfully installed grinding systems

These examples demonstrate TCT Tesic’s global reach in the casting finishing segment.

- MAUS 600 sanding robot – sold to Spain

- SPECTRA GRIND 400 from PS Auto Grinding – sold to the UK

- Stationary deburring station from Koyama – sold to Poland

Grinding systems manufacturers & models

Maus/Reichmann

MAUS 400–600, MAUS 900 – automatic sanding robots

Koyama

Stationary grinding systems for castings

PS Auto Grinding

SPECTRA GRIND, SAM series

More

AutoMet, Reichmann & Sohn

Note: Not all models are always available – TCT Tesic can search for specific types or brands via its network.

Related categories

Discover more used foundry machinery in our portfolio:

- Used blasting systems – for the pre-cleaning of cast parts

- Used moulding machines – for mould production before casting

- Used manipulators – for the safe handling of heavy workpieces

- Used sand preparation – for high-quality moulding sand

Advantages of used grinding systems for foundries

- Cost-efficient: You save on investment costs and receive tried-and-tested technology.

- Robust & industrially proven: Grinding systems for foundries are designed for high loads.

- Immediately available: Shorten project lead times with ready-to-use used machines.

- Specialised for castings: These machines are designed for processing heavy, irregular castings – in contrast to standard grinding machines.

- Act sustainably: By reusing durable machines, you are helping to protect the environment.

FAQ

Foundry grinding systems are significantly more robust and are designed for grinding large, heavy and often irregularly shaped castings. They have special extraction technology and low-vibration designs.

That depends on your range of parts. Automatic grinding centres (e.g. Reichmann/MAUS) are recommended for large quantities and series production. Manual stations are more suitable for flexible processing. TCT Tesic will advise you individually.

The wear condition of the grinding spindle, the guide rails and the extraction system is important. An inspection or test run is often advisable – TCT Tesic will organise this for you.

We record your system technically, advertise it specifically, negotiate with buyers and, if required, also take care of dismantling, transport and export formalities.

Many systems can be overhauled or customised before they are sold – e.. with new controls or workpiece holders. We will be happy to advise you on this.

Why TCT Tesic?

TCT Tesic is your specialist for the trade in used foundry machines – also in the field of grinding technology. You benefit from:

- Market expertise: More than 30 years of experience in the international machinery trade

- Customised advice: technical and commercial support for every project

- Comprehensive service: from documentation to disassembly and assembly

- Worldwide network: access to popular machines, even for specific requirements

- Fast implementation: thanks to earmarked buyers and structured processes

Whether you want to buy or sell a used sanding system – we make sure that everything runs smoothly.

Design & function of a grinding system in the foundry

Grinding systems in foundries are used to remove burrs, smooth cast surfaces and prepare them for further processing steps such as painting or assembly. Typical tasks:

- Deburring: Removal of sharp edges that occur during casting.

- Surface grinding: Levelling out small unevennesses on the casting surface.

- Processing of sprues and risers: mechanical post-processing for mould optimisation.

Types of grinding systems:

- Automatic sanding centres: Robot-controlled systems (e.. MAUS) for high quantities

- Manual stations: For flexible individual processing with operator guidance

- Combination systems: Combination of robotics, grinding wheels, milling spindles and extraction system

Important components:

- Grinding spindle / grinding disc

- Extraction system to minimise dust

- Workpiece fixing / clamping device

- Control system / robot control for automatic systems

Powerful and ergonomic systems are required, especially for cast parts weighing 100-500 kg, to ensure precise finishing – with maximum work safety.

Newsletter & Machine service

Whether you want to buy a used machine or have a machine to sell, we are here to help and advise you.

- Subscribe to our newsletter: Stay up to date with new machine offers and exclusive promotions. Don’t miss out on any opportunities and sign up now.

- Request a machine: Have you seen a suitable machine or do you have specific requirements? Submit your machine request today. We will find the optimal solution for you and get back to you as soon as possible.

- Sell machine: Do you own a core shooting machine that you would like to sell? You’ve come to the right place. Contact us and we will help you sell your core shooting machine – quickly, reliably, and at the best possible price.

TCT Tesic – your partner for comprehensive foundry services. We look forward to your inquiry!

If you have any further questions, please do not hesitate to contact us or use our contact form.