Used induction melting furnaces

Buy or sell used induction melting furnaces – TCT Tesic is your partner for high-performance used melting furnaces in the foundry industry. Whether for grey cast iron, steel, aluminium or iron, whether medium frequency or mains frequency: We provide tested, immediately available induction furnaces, individually tailored to your requirements.

Benefit from an international marketplace for used foundry technology, over 30 years of experience and a comprehensive full service – from transport to commissioning.

Induction melting furnaces

- Position: A13-1.1

- Brand: ABB

- Model: IFM 6/8,4

- Year: 1999

- Capacity: 6000 kW/250 Hz

- Type: Melting plants, Melting plants

Consists of: 2×8 t Induction furnace steel body with furnace lid with fume extraction, tilt frame and hydraulic cylinders 1 x Inverter panel 6000 kW, 250 Hz Melt processor with weighing device 1 x dry

- Position: 101576

- Brand: ALD Vacuum Technologies GmbH

- Model: Leicomelt 2 TP E

- Year: 2008

- Capacity: 10kg Titan - 25kg Superlegierung

- Type: Melting plants, Melting plants

Mainly consists of: Melting and casting chamber Separating valve Pressure relief valve Casting mold lifting device Turret lifting/rotating device with charging valve Vertical charging device Temperature measuring device – thermocouple and pyrometer Leicomelt cold-wall induction

- Position: 101541

- Brand: Hindenlang

- Model: MGB-70

- Year: 2021

- Capacity: 30 Masseln/h

- Type: Melting plants, Melting plants

Mainly consists of: Conveyor belt with casting molds Air cooling molds Mold preheating station with gas burner Control cabinet with frequency converter (speed setting) Transfer and buffer channel for filling the ingots approx. 70 pcs.

- Position: 101540

- Brand: IAS Germany

- Model: MTO 600-1500

- Year: 2021

- Capacity: 600kW; 1kHz

- Type: Melting plants, Melting plants

Mainly consists of: Crucible furnace with tilting chair, hydraulic cylinder, furnace lid and weighing device Hydraulic system with hydraulic control panel and crucible push-out device Furnace platform made of steel IGBT converter type: ITP-2; 600

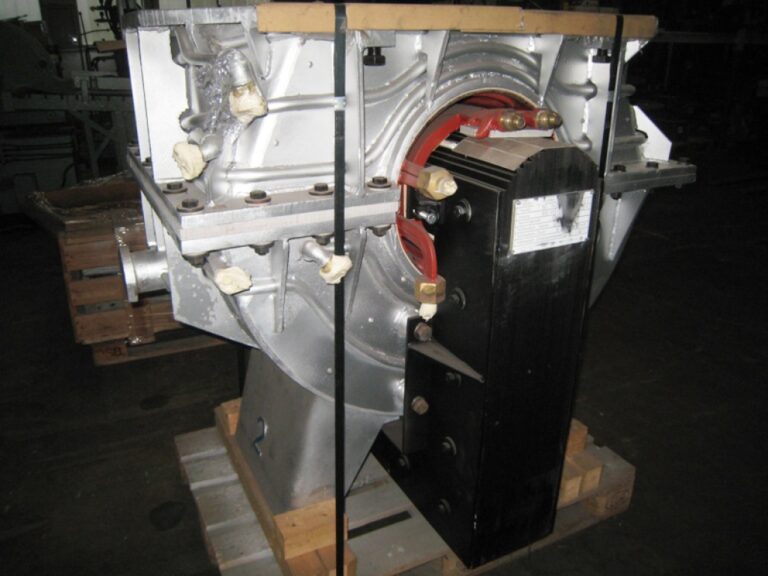

- Position: 101531

- Brand: ABP

- Model: ITK 4000

- Year: 1994

- Capacity: 1.250 kW / 250 Hz

- Type: Melting plants, Melting plants

Mainly consists of: MF-Crucible furnace with tilting chair, hydraulic cylinder without furnace cover Converter: 1,250kW/250Hz new ABP control system GS choke 11.2 mH: 1050A NEW Year: 2014 GS choke 11.2 mH: 1050A Used Year: 1994

- Position: 101525

- Type: Melting plants, Melting plants

Pneumatic shell-type grabs were developed with which slages can be removed from the surface of the bath in the furnace. These slag grips can be attached to the overhead crane. EXW- ex Works, as seen

- Position: 101514

- Brand: Foundry Service

- Year: 2009 / 2018

- Capacity: 15 t Volumen

- Type: Melting plants, Melting plants

Mainly consisting of: Crane casting ladle with handwheel and compressed air motor (conversion 2018) With treatment lid and delivery template Dimensions: Width = approx. 3.518 mm Height = approx. 4.540 mm Depth = approx. 2.260

- Position: 101511

- Model: KG 10

- Capacity: 5,5 t Volumen

- Type: Melting plants, Melting plants

Mainly consists of: Steel vessel Pan traverse Planetary gearbox type: SG 182 with manual drive Ladle book Transport trolley Lining 1.5 tons As seen, ex works Germany

- Position: 101512

- Model: KG 12

- Capacity: 6,5 t Volumen

- Type: Melting plants, Melting plants

Mainly consists of: Steel vessel Pan traverse Planetary gearbox type: SG 182 with manual drive Ladle book Transport trolley lining 1.9 tons As seen, exw Germany

- Position: 101412

- Brand: ABP

- Model: LFR 30

- Year: 2017

- Capacity: 1.000 kW

- Type: Melting plants, Melting plants

Furnace body holding cap. 45 t gross / 30 t net Mainly consists of: Furnace body with inductor and tilting chair with hydr. cylinder Hydraulic unit with control desk Three-phase-oil-stepdown-transformer 1250 kVA, 20.000 +/- 5

- Position: 101189

- Brand: ASEA / ABB

- Model: LRI 5

- Capacity: 500 kW

- Type: Melting plants, Melting plants

Technical data: – frequency: 50 Hz – rated voltage: 530 V – rated current: 1720 A – nominal temperature: 1500°C

Successfully brokered used melting furnaces

We have many years of experience and have already successfully brokered numerous used induction melting furnaces:

- ABP MF 6 tonne induction furnace - sold to a foundry in Turkey (2023)

- Junker 3.5 MW melting plant - brokered to Italy (2021)

- Inductotherm Twin Power 12 to - sold to a steelworks in South America (2020)

- ABP 30t induction melting furnace - sold to a Czech steel foundry (2024)

Induction melting furnace manufacturers & models of induction melting furnaces

TCT Tesic supports you in buying and selling used melting furnaces from leading manufacturers. Whether medium frequency, mains frequency or special furnaces – we will help you to find the right solution for your requirements. Below is an overview of common suppliers and their most sought-after industrial induction melting furnace models:

ABP Induction

Junker (Otto Junker)

MFT, MFTS, MFTQ – for iron, non-ferrous metals, special alloys, foundries & forges

Inductotherm

VIP Power-Trak®, Twin-Trak®, Radyne – modular, energy-efficient industrial ovens

NABERTHERM

Small furnaces for laboratory & precious metals – ideal for gold, silver, prototype production

Note: The machines of these manufacturers are not always immediately available. However, TCT Tesic can use its international network to search for specific models – simply submit a customised machine enquiry.

Related machine categories

Discover additional used foundry machines in our portfolio:

- Buy used moulding lines - complete moulding lines for green sand & box operation

- Used sand preparation systems - mixers, cooling systems, regeneration

- Used blasting systems - Cleaning technology for castings

- Buy used core shooters - cold box, hot box & special processes

Used induction ovens - advantages at a glance

- Cost savings: Second-hand induction melting furnaces are significantly cheaper than new purchases.

- Availability: Industrial induction melting furnaces are available for immediate delivery – without months of production time.

- Tested technology: systems from ongoing operation – ready for use, maintained & documented.

- Sustainability: Conserve resources by reusing instead of producing new products.

- Flexibility: Different performance classes & tonnages – suitable for every casting process.

FAQ

Induction melting furnace design: Medium-frequency furnaces offer more precise temperature control and faster heat-up times – ideal for different types of metal. Mains frequency furnaces are simpler in design, less expensive, but less flexible.

The condition, year of manufacture, output, control system, melting volume and accessories (e.g. converter, casting ladles) are important. Pay attention to existing documentation and, if necessary, test runs.

Induction melting furnace explanation: Yes – many induction furnaces can also be used as holding furnaces, e.g. for continuous casting processes.

Generally much faster than new systems – after dismantling, transport and reassembly, often within a few weeks.

We provide such specialised systems on a project basis – please contact us directly.

New or used: TCT Tesic is your contact - also for new Plasma Induction systems

In addition to the international trade in used induction melting furnaces, TCT Tesic is the official sales representative of the Indian quality manufacturer Plasma Induction – an established supplier of modern induction furnaces and melting systems.

Whether you are looking for a new system or want to supplement an existing furnace line: Plasma Induction offers an excellent price-performance ratio, robust technology and globally proven solutions for the metalworking industry.

Your benefits with Plasma Induction:

- Customised new systems for the foundry, steel and metal industry

- Modern control technology, high energy efficiency, short delivery times

- Technical design & advice from TCT Tesic in Germany

- Complete service: from planning to commissioning

Contact us if you are interested in a new machine in addition to used systems – we will work with you to find the solution that best suits your needs both economically and technically.

Services from TCT Tesic around melting furnaces

We offer you more than just trading in machines:

- Consultancy & needs analysis: support with the selection of oven type, size, output & accessories

- Purchase & sale: We market or procure used melting technology in a targeted manner

- Dismantling & packaging: Professional dismantling incl. component documentation

- Logistics & export: transport handling incl. customs, worldwide

- Commissioning & training: Reconstruction, fine-tuning & employee instruction on site

Induction melting furnace function

An induction melting furnace is used for melting and tempering metals such as grey cast iron, steel, aluminium or iron. The technology utilises electromagnetic induction to heat and melt metallic materials without contact.

Typical components:

- Furnace vessel (crucible) – usually made of ceramic material to hold the molten metal

- Induction coil – generates the electromagnetic field for heating

- Cooling circuit & switch cabinet – for temperature regulation and control

- Inverter & switchgear – Conversion of mains current into frequency ranges for the magnetic field

- Tilting mechanism or crane ladle – for pouring the molten metal into the moulds

- Control systems (e.. Siemens S7) – for process monitoring and safety control

Frequency types:

- Medium-frequency furnaces (MF) – widely used for large tonnages and flexible use (1-30 tonnes)

- Mains frequency ovens (NF) – simple technology, robust, ideal for continuous operation

Melting performance:

- Power range from 250 kW to 10 MW

- Melting volume from 1 to 30 tonnes

- Typical casting temperatures: up to 1,600 C°

Material

- Aluminium induction melting furnace

- Gold induction melting furnace

- Grey cast iron induction melting furnace

- Steel induction melting furnace

Newsletter & Machine service

Whether you want to buy a used machine or have a machine to sell, we are here to help and advise you.

- Subscribe to our newsletter: Stay up to date with new machine offers and exclusive promotions. Don’t miss out on any opportunities and sign up now.

- Request a machine: Have you seen a suitable machine or do you have specific requirements? Submit your machine request today. We will find the optimal solution for you and get back to you as soon as possible.

- Sell machine: Do you own a core shooting machine that you would like to sell? You’ve come to the right place. Contact us and we will help you sell your core shooting machine – quickly, reliably, and at the best possible price.

TCT Tesic – your partner for comprehensive foundry services. We look forward to your inquiry!

If you have any further questions, please do not hesitate to contact us or use our contact form.