Foundry Partners

PARTNER

Your partner in the foundry industry

With our foundry partners division, we offer companies from other industries the opportunity to sell their products and services in the foundry industry.

We are also able to offer foundries the opportunity to offer their casting production for other industries.

With our huge reputation, many years of experience and several thousand direct contacts, you already have access to a successful established distribution structure. In addition, we take care of initial contacts, inquiries and processing the order.

Mains and medium frequency capacitors

We are a distributor of capacitors in Europe of 50Hz- and medium frequency capacitors according to the latest EU standards, particularly suitable for induction furnaces:

- MF & HF Water Cooled Capacitors

- Medium & High Voltage Capacitors

- Low Voltage Capacitors

- Surge Protection Capacitors

- Energy Storage Capacitors

- APFC Panels

TECHNICAL SPECIFICATIONS:

OUTPUT Upto 8,400 kVAr

VOLTAGE Upto 4,000 Volts AC

FREQUENCY Upto 20,000 Hz

TAPPINGS Topped / Untopped

PHASE Single Phase.

COOLING Water Cooled

MOUNTING Horizontol / Vertical.

CASING Aluminum / Brass

CASE DESIGN lsolated (Deod) / Live Cose

PROTECTION Thermal & Over Pressure

STANDARDS IEC & EN:601 1O-1/2,lSS:9251

ENHANCHING THE POWER OF INDUCTION!

For further information and inquiries, please contact us.

Induction Heating, Melting, Hardening and Special Equipment

Our Partner, has been a leading developer and provider for Induction Heating, Melting, Hardening and Special Equipment’s in the Indian and International market.

Started the journey in 2012 with more than 120+ Qualified Team members, they have positioned themselves as a HIGH-QUALITY & PRECISE INDUCTION EQUIPMENT manufacturer.

Taking utmost care, products are designed with efficiency to cater to their customers, and that is why the customer satisfaction rate is almost 98% & sales have increased drastically.

TCT Tesic is the official distribution partner in the european market and will be of service to its clients and partners in terms of all the distribution and communiction process.

If you have further comments or questions, please feel free to contact us any time.

Manipulatoren

The most advanced manipulator system for foundries, forges and steel mills.

In most foundries that produce large series of castings and these have to be sorted out and loaded afterwards, the Andromat manipulators from Henschel Industrietechnik GmbH will most likely be in use.

For the national and international sale of used manipulators, TCT Tesic cooperates with the manipulator manufacturer Henschel Industrietechnik GmbH.

If you would also like to sell your manipulators or are looking for new used machines, please do not hesitate to contact us at any time.

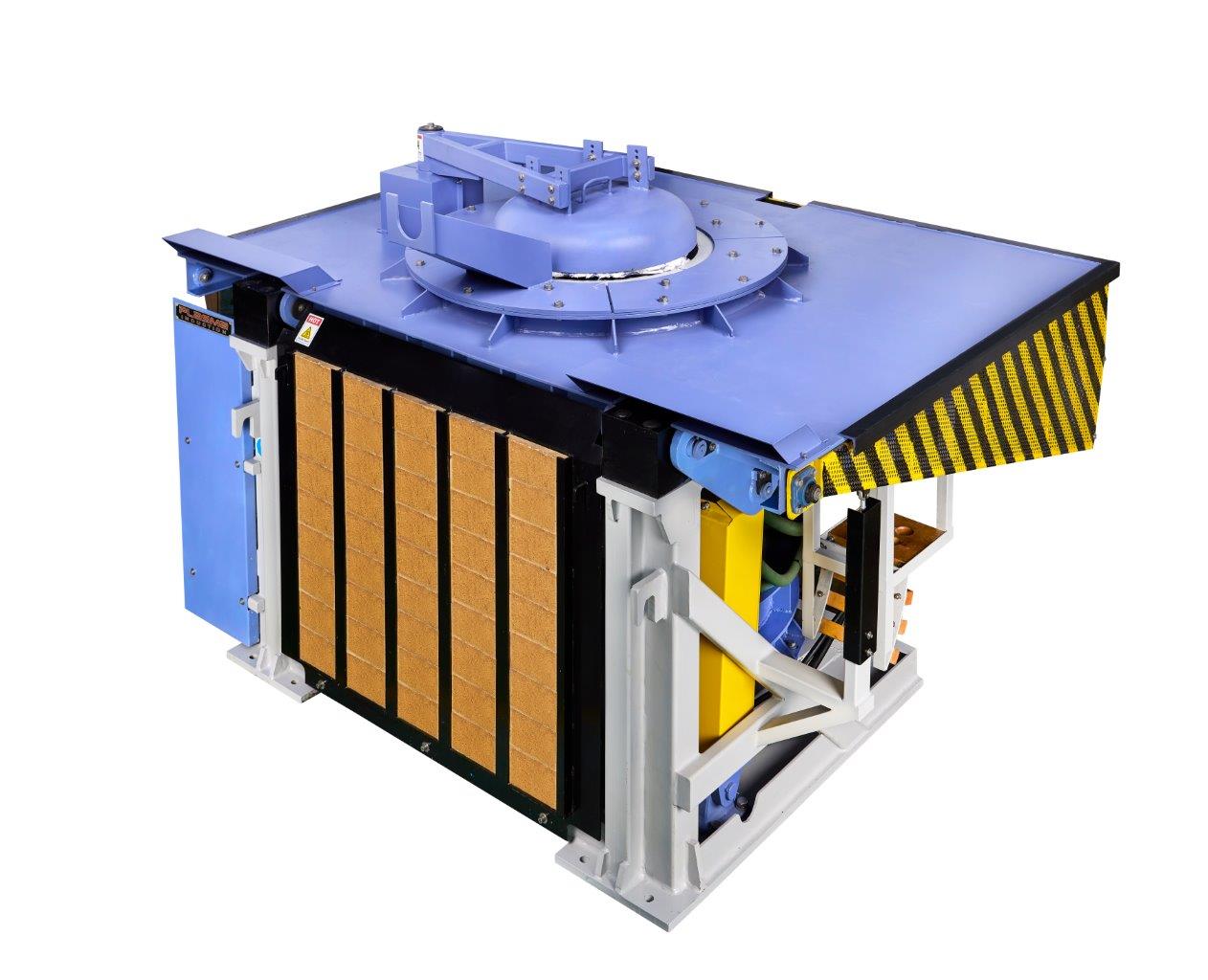

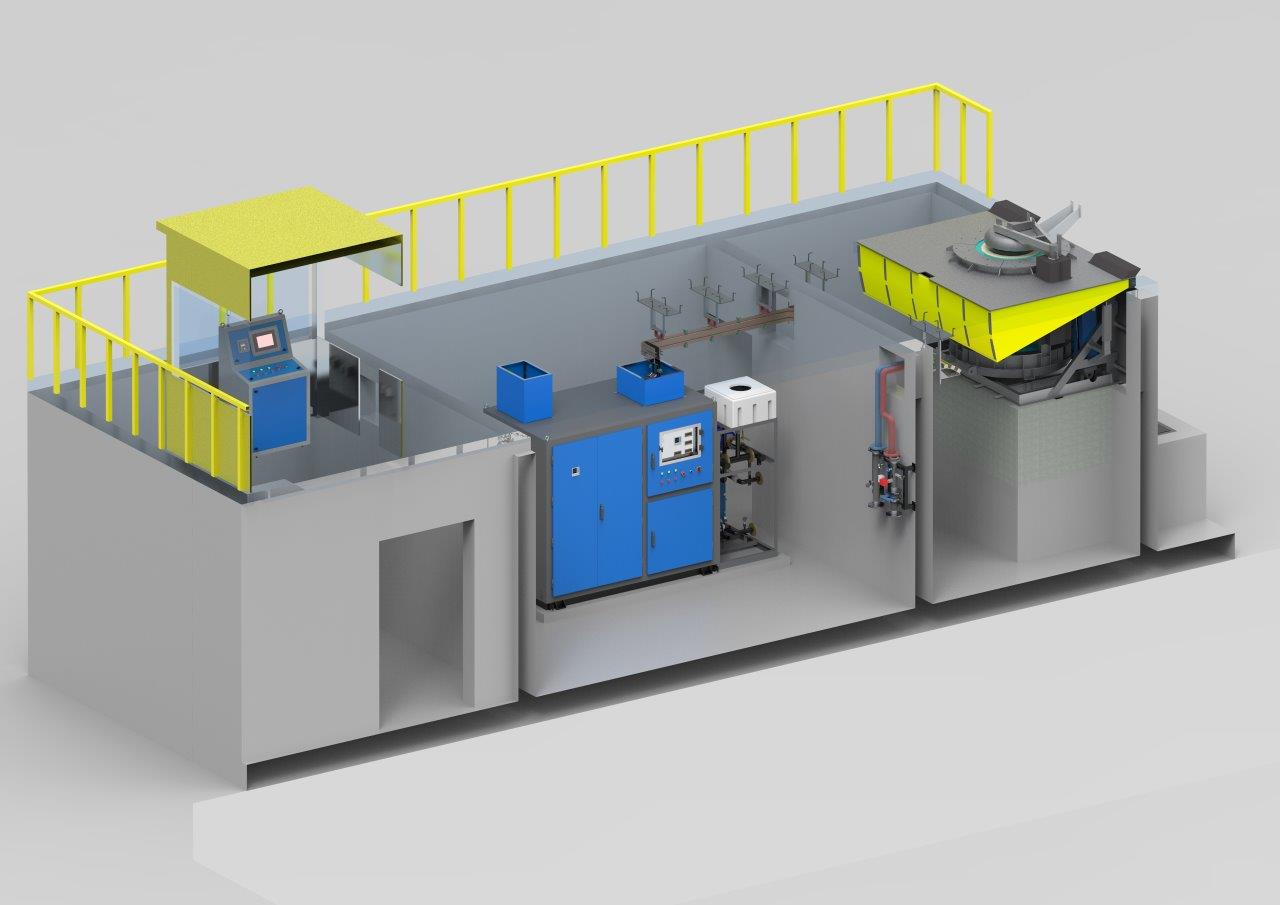

Low-pressure casting systems and service

We support our partner company in selling their low-pressure casting systems and offer first-class technical service at the same time for existing low-pressure casting systems of various makes.

The company was founded in 2020 and comes from a tradition of more than 50 years of experience in the development, design and manufacture of cast products and machines in the field of aluminum low-pressure casting as well as in Magnesium field..

The company manufactures low pressure die casting machines that are precisely tailored to customer needs and supports customers in all areas of their aluminum foundry.

Customer support is also possible in research and development, design and production, as well as in terms of quality and certification.

For more information, please contact us directly at any time!

advantages:

Casting machines:

- Specially designed for wheel casting.

- Low scrap (e.g. 1st wheel after filling is ok)

- Compact design (can be walked on all around)

- Low working height, therefore low working platforms.

- Simple operation and therefore also suitable for beginners

- Very robust and low maintenance construction

- Crucible furnace with low energy consumption due to thyristor control

- Best insulation – energy/cost saving

- Clamping unit with 4-column guide and 4 hydraulic cylinders

- High clamping forces

- Fast riser change, easy furnace maintenance.

- Operator-friendly, programmable microprocessor control (PLC) with process visualization via color monitor, direct display of messages

- Reduction of non-productive time

- Highest melt quality – best casting quality

Mold building:

- 3D design

- Casting and solidification analysis

- Weight optimization

- short delivery times

Consulting:

- more than 50 years of experience in casting light alloy wheels

- consulting and preparation of certification procedures

- consulting for entire production of light alloy wheels. (casting, machining painting, quality control)

- favorable long-term consulting and consulting contracts.