- Position: A13-1.9

- Brand: DISA Wheelabrator

- Model: ML-12/0518-202

- Year: 2003 (Umbau)

- Capacity: 272 kg

- Type: Fettling shops, Fettling shops

Mainly consist of: Blasting chamber with double doors Monorail steel construction with hooks and transport chain Blasting media bucket elevator Screw conveyor Control and operating cabinet with PLC controls Number of blast wheels 12 Drive

- Position: A13-1.8

- Brand: RÖSLER

- Model: RHBD 15/20 - T

- Year: 2008

- Type: Fettling shops, Fettling shops

Mainly consists of: Blasting chamber with double doors Monorail steel construction with turning devices and hooks Abrasive bucket elevator Screw conveyor Control and operating cabinet with SIEMENS PLC S7 Number of blast wheels: 4 Total

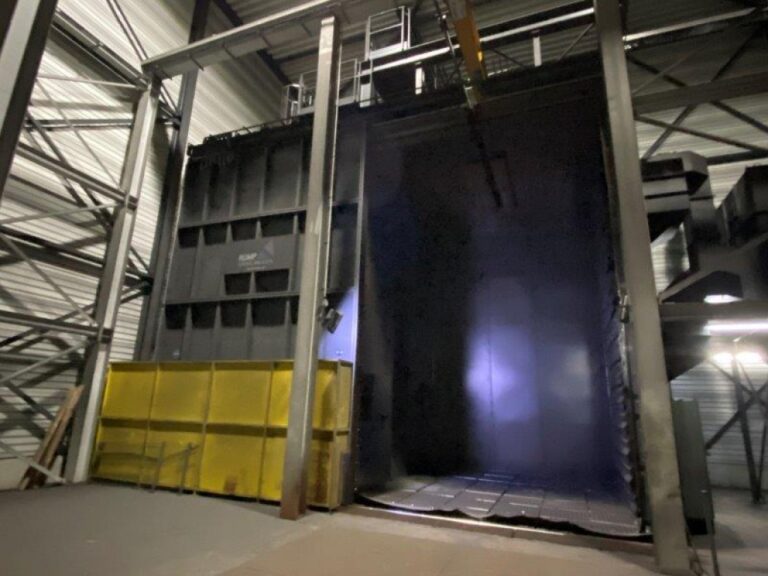

- Position: A13-1.7

- Brand: RUMP

- Model: 20-D-1250

- Year: 1995

- Capacity: 6,0 m/s

- Type: Fettling shops, Fettling shops

Mainly consists of: Shot blast chamber: LxWxH: 4700x 1800x 2850 mm 8 nos. Turbo blast wheels Typ TSM IV / Connected load: 15/12 KW Bucket elevator Longit. Screw conveyor Transport wire belt Width: 1250 mm

- Position: A13-1.6

- Brand: EIRICH

- Year: 1992

- Capacity: 150 t/h

- Type: Sand plants, Sand plants

Mainly consists of: 2 no. sand mixers Make: EIRICH Type: DW29/4 Both mixers will be overhauled in 2024 (value: 100K) 1 no. Rotocontrol Sand tester Make: EIRICH 1 no. Sand cooler Make: EIRICH MC200 -1

- Position: A13-1.5

- Brand: EIRICH

- Year: 1992

- Capacity: 150 t/h

- Type: Sand plants, Sand plants

Mainly consists of: 2 no. sand mixers Make: EIRICH Type: DW29/4 1 no. Rotocontrol Sand tester Make: EIRICH 1 no. Sand cooler Make: EIRICH MC200 -1 no. overbelt magnet separator 1 no. polygonal rotary sieve

- Position: A13-1.32

- Brand: Padeltherm

- Model: Siemag

- Year: 1990

- Capacity: 1000 kg Nutzlast / Palettengröße 800 x 1200 mm u. 1000x 1200 mm

- Type: Core shops

Consists of: Travel drive Platforms Lifting mast Hoisting unit Safety catch device Steel structure / frame Access ladder Roller guide system Cabin Electrical control cabinet without dismantling, as seen, exw Germany

- Position: A13-1.31

- Brand: Padeltherm

- Year: 2013

- Capacity: 300 kW (4 x 75kW)

- Type: Core shops

Consists of: Oven Combustion air fan Pressure monitoring system Burner Circulation fans Control system without dismantling, as seen, exw Germany

- Position: A13-1.30

- Brand: Padeltherm

- Year: 2013

- Capacity: 300 kW (4 x 75kW)

- Type: Core shops

Consists of: Oven Combustion air fan Pressure monitoring system Burner Circulation fans Control system without dismantling, as seen, exw Germany

- Position: A13-1.3

- Brand: HWS Heinrich Wagner Sinto

- Model: EFA-SD 8

- Year: 1995

- Capacity: 70 Fo./h

- Type: Moulding shops, Moulding shops

Mainly consists of: Flask size: 2,000 x 1,500 x 250/250 mm Capacity: min. 70 molds per hour Cycle time: 25.7 seconds. Moulding machine SEIATSU air flow press moulding process Automatic pattern changer Flask turnover device

- Position: A13-1.29

- Brand: Segab

- Year: 2008

- Type: Core shops

Consists of: Main machine Mobile mixer Sand dosing unit Day hoppers for sand, resin, and hardener Dosing pumps (dosing unit) Feeding trolley Feeding screws Electric cabinet without dismantling, as seen, exw Germany

- Position: A13-1.21

- Brand: Nedermann

- Year: 2008

- Capacity: 90.000 m3/h

- Type: Dedusting

Consists of: Dust filter unit Axial cyclone separator for pre-separation of coarse particles Clean air ducting including all necessary connections Induced draft fan Central control cabinet for system operation Complete piping and ductwork Extraction hoods

- Position: A13-1.20

- Brand: Lühr

- Year: 2008

- Capacity: 35.000 m3/h

- Type: Dedusting

Consists of: Dust filter unit Axial cyclone separator for pre-separation of coarse particles Clean air ducting including all necessary connections Induced draft fan Central control cabinet for system operation Complete piping and ductwork Extraction hoods

- Position: A13-1.2

- Brand: HWS Heinrich Wagner Sinto

- Model: EFA-SD 6

- Year: 1992

- Capacity: 220 Fo./h

- Type: Moulding shops, Moulding shops

Mainly consists of: Flask size: 1.250 x 880 x 220/220 mm Capacity: min. 220 molds per hour Cycle time: 18 seconds. HWS Project no. 10551 2 nos. Moulding machines SEIATSU air flow press moulding process

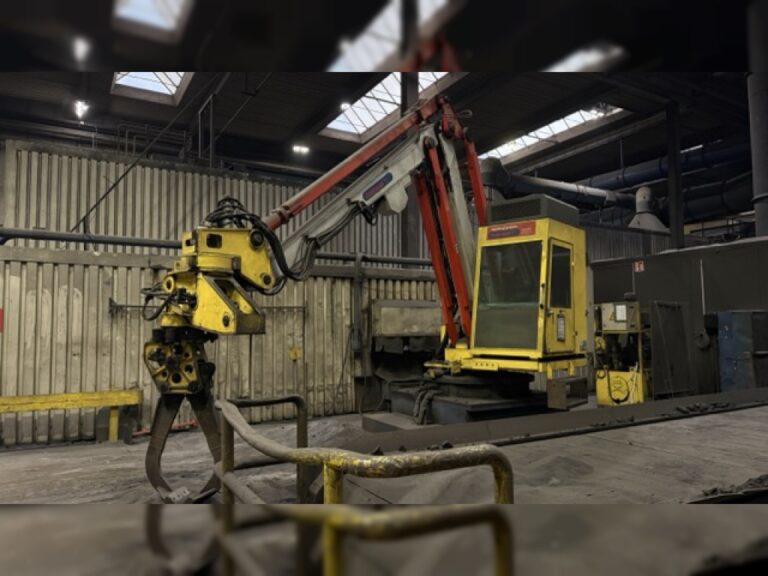

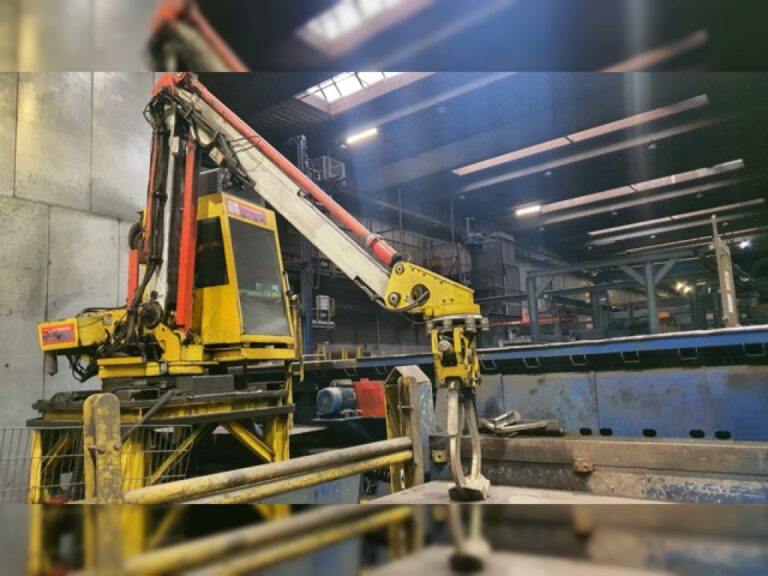

- Position: A13-1.17

- Brand: Thyssen Henschel

- Model: Andromat AM 2000 / T5

- Year: 1999

- Capacity: Armlänge ca. 5m

- Type: Conveying

Consists of: Manipulator Electric Cabinet Hydraulic Techn. Documentation without dismantling, as seen, exw Germany

- Position: A13-1.16

- Brand: Thyssen Henschel

- Model: Andromat AMX 60 T6-T5

- Year: 2005

- Capacity: Armlänge ca. 5m / Handling: ca. 1000 kg

- Type: Conveying

Consists of: Manipulator Electric Cabinet Hydraulic Techn. Documentation without dismantling, as seen, exw Germany

- Position: A13-1.15

- Brand: Thyssen Henschel

- Model: Andromat AM 2000 / T5

- Year: 1995

- Capacity: Armlänge ca. 5m

- Type: Conveying

Consists of: Manipulator Electric Cabinet Hydraulic Techn. Documentation without dismantling, as seen, exw Germany

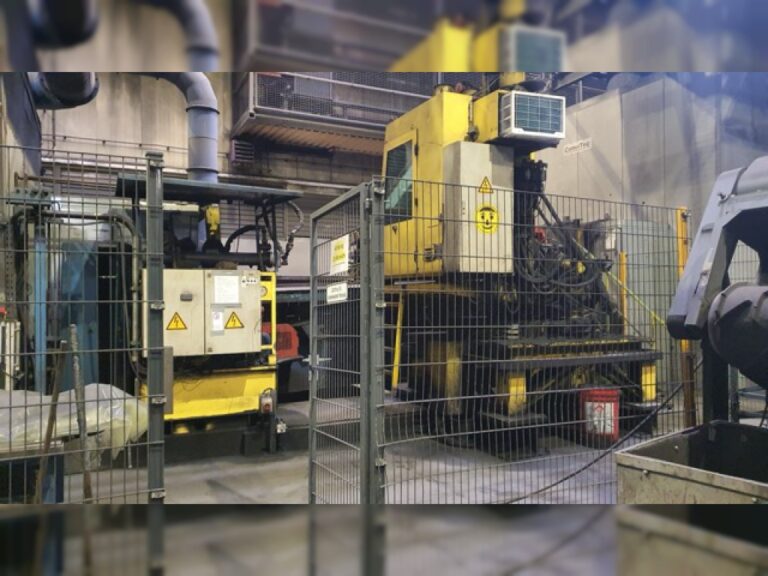

- Position: A13-1.14

- Brand: Thyssen Henschel

- Model: Andromat AM 550 / T5

- Year: 1993

- Capacity: Armlänge 5m

- Type: Conveying

Consists of: Manipulator Electric Cabinet Hydraulic Techn. Documentation without dismantling, as seen, exw Germany

- Position: A13-1.11

- Brand: Pour-tech AB

- Model: PT1

- Year: 2016

- Type: Melting plants

Mainly consists of: Water treatment station TYPE RAS 40 Components included: RAS 20 conductivity meter with measuring cell RAS 40 conductivity meter with measuring cell Dosing station for anti-corrosion agent RAS-KI VE cartridge with ion

- Position: A13-1.1

- Brand: ABB

- Model: IFM 6/8,4

- Year: 1999

- Capacity: 6000 kW/250 Hz

- Type: Melting plants, Melting plants

Consists of: 2×8 t Induction furnace steel body with furnace lid with fume extraction, tilt frame and hydraulic cylinders 1 x Inverter panel 6000 kW, 250 Hz Melt processor with weighing device 1 x dry

- Position: A12-03

- Brand: Jost

- Model: TWFE 1200 & FSL 1200

- Capacity: 8,5t/h

- Type: Conveying, Conveying

Mainly consists of: 1 Jost Shakeout machine (upper part ) TWFE 1200/1382 – 300×6200 with 2 Motors Jost 4 WE 1500/160 M 400V 50Hz 1 Sand conveyor (underneath part) FSL 1200 /1300 – 100×10000 with

- Position: A12-01

- Brand: DISA

- Model: 2070 A

- Year: 1990

- Capacity: 160 - 250 moulds / h

- Type: Moulding shops, Moulding shops

Chamber size: Height 700 mm / Widht 950 mm Mould thickness 200 – 650 mm Mainly consists of: Moulding Machine (DMM – 5,9 Mil. original moulds produced only until now) SSU PMC 14 m SBC

- Position: A11-32

- Brand: HYNDAI Korea

- Model: L230A Fanuc i Series

- Year: 2014

- Type: Various, Various

Mainly consists of: 1x CNC Turning Center including chip transport Technical data: Maximum distance above the bed Ø 600 mm Maximum turning diameter Ø 355 mm Maximum turning length 440 mm Maximum bar diameter mm

- Position: A11-04

- Brand: EURO-EQUIP

- Model: AP 900-50

- Year: 2015

- Capacity: 5 - 8 t/h

- Type: Fettling shops, Fettling shops

Mainly consists of: Main body of the crusher Hydraulic unit Electric cabinet Hopper – inkl. Protection and support structure Skip loader and its support structure Vibrating conveyor 900 x 3500 mm As seen, ex works,

- Position: 101576

- Brand: ALD Vacuum Technologies GmbH

- Model: Leicomelt 2 TP E

- Year: 2008

- Capacity: 10kg Titan - 25kg Superlegierung

- Type: Melting plants, Melting plants

Mainly consists of: Melting and casting chamber Separating valve Pressure relief valve Casting mold lifting device Turret lifting/rotating device with charging valve Vertical charging device Temperature measuring device – thermocouple and pyrometer Leicomelt cold-wall induction

- Position: 101575

- Brand: MAUS s.r.l. Italien

- Model: SAM 300G

- Year: 2020 (WIE NEU)

- Capacity: Max. 40 kg

- Type: Fettling shops, Fettling shops

Max. part weight: 40 kg Max. part height: 290 mm Max. part swing: 450 mm Mainly consists of: Complete Grinding cell Automatic Pallet Changer Part Measuring Laser System The machine is NEW and was not

- Position: 101573

- Brand: Eirich

- Model: RV23 VAC

- Year: 1998

- Capacity: 55to/h

- Type: Sand plants, Sand plants

Mainly consists of: Sand Mixer Type: RV23VAC Mixing Volume: 3.0 m³ Capacity: max. 50 t/h Used Sand Temperature: max. 90°C Finished Sand Temperature: 40°C Connected Power: 320 kW Also: Sand Cooler Polygon Screen: Type PD

- Position: 101569

- Brand: F.G. Wilson

- Model: P77E

- Year: 1996

- Capacity: 61 kW

- Type: Various, Various

Essentially consisting of: Emergency generator 77kVA; 61.6 kW; 400/230V; 111.1A Revolutions: 1500 Weight: 1138 kg With diesel generator Manufacturer: Perkins Exciter voltage: 39V Exciter current: 1.95A Voltage regulator: SX 460 Sold as seen, EXW

- Position: 101568

- Brand: ?

- Model: TEIN 250

- Year: 1990

- Capacity: 250 kVAr

- Type: Various, Various

Mainly consists of: Rated voltage: 945 V Rated current: 265 A No.: 9026108 Weight: 530 kg Sold as seen, EXW

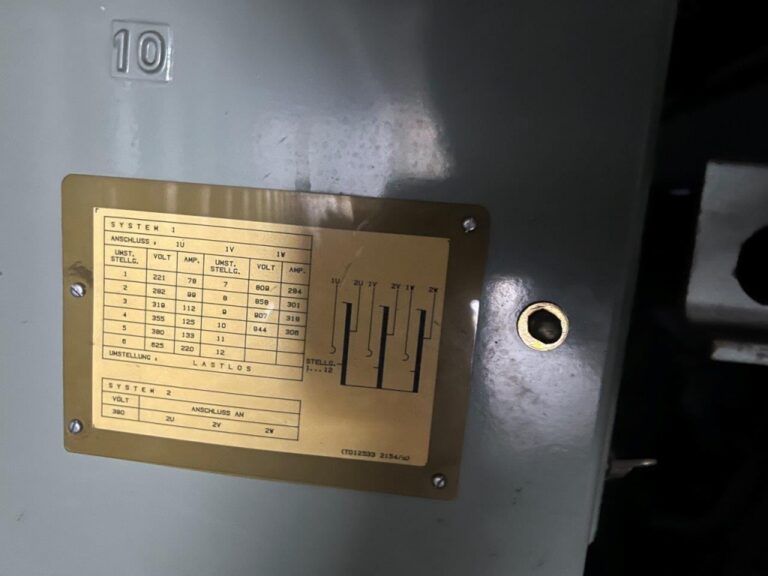

- Position: 101567

- Brand: ?

- Model: TDR 305

- Year: 1990

- Capacity: 500 kVA

- Type: Various, Various

Mainly consists of: DS dry-type step transformer 500 kVA R2 No. 9026105 Sheet metal package with 3 coils + P&O tap changer Rated voltage 380/221 — 907 — 944V Rated current: 760-45/78 — 318 —

- Position: 101566

- Brand: ?

- Model: TDR 305

- Year: 1990

- Capacity: 500 kVA

- Type: Various, Various

Mainly consists of: DS dry-type step transformer 500 kVA R1 No. 9026106 Sheet metal package with 3 coils + P&O tap changer Rated voltage 380/221 — 907 — 944V Rated current: 760-45/78 — 318 —

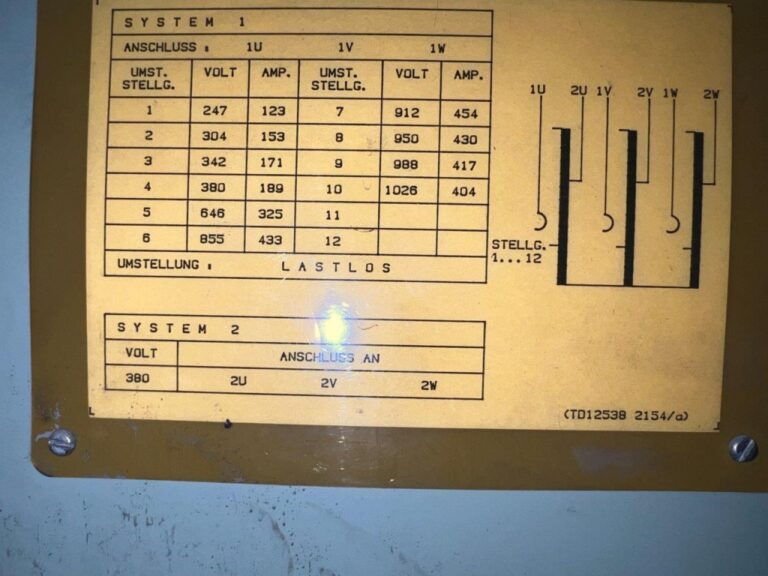

- Position: 101565

- Model: TER 470

- Year: 1990

- Capacity: 700 kVA

- Type: Various, Various

Mainly consists of: DS dry-type tapped transformer 700 kVA No. T1 No. 9026101 Sheet metal package with 3 coils + P&O tap changer Rated voltage 380/247 — 912 — 1026V Rated current: 80-1091/123 — 454

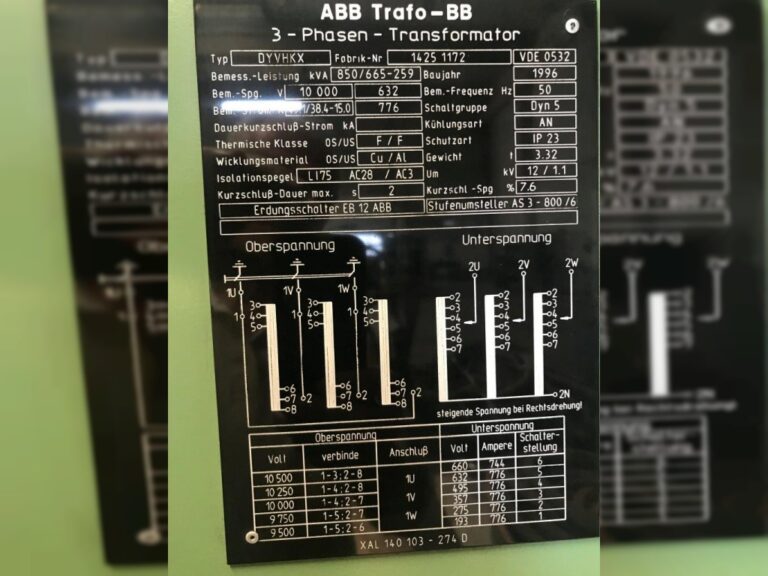

- Position: 101564

- Brand: SGB

- Model: DTTHF

- Year: 1999

- Capacity: 850 kVA

- Type: Various, Various

Mainly consists of: DS dry-type step transformer 850 kVA No. 204257 Sheet metal package with 3 O-coils + U-coils 11 contactors Control cabinet with cables Rated voltage 10,000 +- 5% / 632 V in 6

- Position: 101563

- Brand: SGB

- Model: ETD 500

- Year: 2000

- Capacity: 500 kVAr

- Type: Various, Various

Mainly consists of: No. 204676 Rated voltage: 660 V // 50 Hz Rated current: 758 A Cooling type: AN Total weight: 1.18 t

- Position: 101562

- Brand: SGB

- Model: ETDH 315

- Year: 2000

- Capacity: 335 kVAr

- Type: Various, Various

Mainly consists of: Rated power: 335 kVAr // No. 204287 Rated voltage: 675 V // 50 Hz Rated current: 495 LxWxH 1320x800x1800 Total weight: 1.25t Sold as seen, EXW

- Position: 101561

- Brand: ABP

- Model: ID-8

- Year: ?

- Capacity: 800kW

- Type: Various, Various

Mainly consists of: 1 steel chute ready for installation Sold as seen, EXW

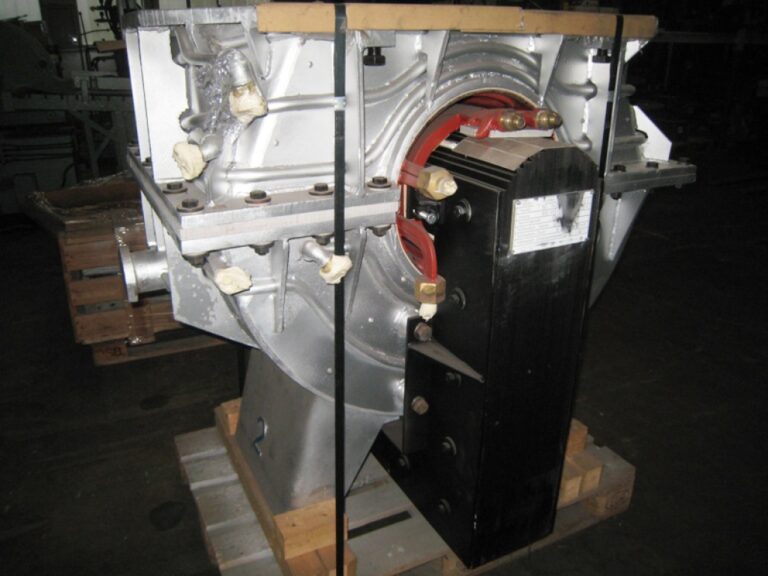

- Position: 101560

- Brand: ABP

- Model: ID-8

- Year: 1999

- Capacity: 800kW

- Type: Various, Various

Mainly consists of: Channel inductor 800 kW Channel furnace core WF coil WF cylinder with steel vessel Total weight: 5.4 t Sold as seen, EXW

- Position: 101559

- Brand: ?

- Model: ODRN 850

- Year: 1989

- Capacity: 850kVA

- Type: Various, Various

mainly consists of: Ds-Oel step transformer 850kVA No. 8926048 Rated voltage: 20,000 +/- 5% // 180 – 780 V / 8 steps Rated current: 24.5 – 5.98 / 663 – 629 A Switching size: DY5

- Position: 101556

- Brand: Foundry Service

- Model: Auftr. 11676

- Year: 2017

- Capacity: 750 kg

- Type: Various, Various

Mainly consists of: Pour Ladle hanger Drum body (drum vessel) Tilting device (gearbox with handwheel) Type: RSD 60V, / Nr. 40709 / 004 Further technical data, see our web With Ladle book, main inspection and

- Position: 101555

- Brand: Foundry Service

- Model: Auftr. 1175

- Year: 2017

- Capacity: 500 kg

- Type: Various, Various

Mainly consists of: Pour Ladle hanger Drum body (drum vessel) Tilting device (gearbox with handwheel) Type: RSD 60V, / 40709/0005 Further technical data, see our web With Ladle book, main inspection and approval 2024

- Position: 101554

- Brand: DISA

- Model: 2110 MK3

- Year: 1999

- Capacity: 275 - 300 Formen pro Stunde

- Type: Moulding shops, Moulding shops

Mainly consists of: DISAMATIC Model 2110 Mk3 Allen Bradley PLC Upgraded VDU Automatic Core Setter Automatic Spray System 12 Meter AMC Technical Data: Mold Dimensions: Height: 400 mm (15.7 inches) Width: 500 mm (19.7 inches)

- Position: 101550

- Brand: Marbaise

- Model: RSD 140V

- Year: ?

- Capacity: 32.000Nm

- Type: Conveying, Conveying

Planetary gearbox RSD 140V for up to 30 ton pouring ladle Nominal torque: 32,000 Nm T-max.: 51,600 I-ratio: 203 Shaft journal diameter: 140 mm

- Position: 101545

- Brand: SPECTRO

- Model: SPECTROTEST TXC 03

- Year: 2012

- Capacity: Eisen, Aluminium, Nickel und Stahl

- Type: Measure, Measure

Mainly consists of: Portable spectrometer for metal analysis of iron, aluminum, nickel, and steel Housing Screen Storage compartment Probe holder Trolley Probe Argon cylinder holder Air filter CO2 and particulate matter filter EXW – ex

- Position: 101541

- Brand: Hindenlang

- Model: MGB-70

- Year: 2021

- Capacity: 30 Masseln/h

- Type: Melting plants, Melting plants

Mainly consists of: Conveyor belt with casting molds Air cooling molds Mold preheating station with gas burner Control cabinet with frequency converter (speed setting) Transfer and buffer channel for filling the ingots approx. 70 pcs.

- Position: 101540

- Brand: IAS Germany

- Model: MTO 600-1500

- Year: 2021

- Capacity: 600kW; 1kHz

- Type: Melting plants, Melting plants

Mainly consists of: Crucible furnace with tilting chair, hydraulic cylinder, furnace lid and weighing device Hydraulic system with hydraulic control panel and crucible push-out device Furnace platform made of steel IGBT converter type: ITP-2; 600

- Position: 101538

- Brand: BMD

- Model: AM (S) 135.90

- Year: 2022

- Capacity: 8 - 10 Fo/h

- Type: Moulding shops, Moulding shops

Flask size: LxBxH: 1350 x 900 x 400 / 400 mm Mainly consists of: 1 Moulding machine 5 Cope & 5 Drag Flasks 1 set Filling frame (for each cope & drag) 1 set Pattern

- Position: 101536

- Brand: Dosiertechnik GmbH DE

- Model: UR 1000/4045-S

- Year: 2024

- Capacity: 2 x 3,2 kW

- Type: Conveying, Conveying

Mainly consists of: 1x Vibratory conveyor with 2 nos. unbalanced drives Technical data: Power: 2x 3.2 kW Weight: 1640 kg Dimensions: 4080 x 1190 x 1080 mm Drive type: 2 x R3500/6 Voltage: 400 V

- Position: 101533

- Capacity: 4,25 x 5,0 m - 50 t

- Type: Sand plants, Sand plants

Sand throughput: 90 t per 12,5 h average Sank temperature at knockout: 300-400 °C The Shakeout deck is manufactured from 70 mm thick mild steel with D050 mm apertures covered by 20 mm thick Hardox

- Position: 101532

- Brand: HWS / Eirich

- Model: HSP 1

- Year: 2004

- Capacity: 35 Fo/h

- Type: Moulding shops, Moulding shops

Sand Mixer capacity of 500 kg Mainly consists of: Seiatsu HSP1 Moulding Machine: Moulding size: 650 x 500 x 200/200 mm / 35 moulds per hour Flask manipulator – Flask conversion equipment – Silos –

- Position: 101525

- Type: Melting plants, Melting plants

Pneumatic shell-type grabs were developed with which slages can be removed from the surface of the bath in the furnace. These slag grips can be attached to the overhead crane. EXW- ex Works, as seen

- Position: 101518

- Brand: Neuhof

- Year: 2013

- Capacity: 5.000 kg

- Type: Various, Various

Mainly consists of: 1x coring table (table size: W = 2.50 m; depth = 1.8 m; height = 1.24 m) 2x pneumatic chain tensioners 2x balancing motors with 6.5 kW each (frequency controlled + freely

- Position: 101514

- Brand: Foundry Service

- Year: 2009 / 2018

- Capacity: 15 t Volumen

- Type: Melting plants, Melting plants

Mainly consisting of: Crane casting ladle with handwheel and compressed air motor (conversion 2018) With treatment lid and delivery template Dimensions: Width = approx. 3.518 mm Height = approx. 4.540 mm Depth = approx. 2.260

- Position: 101512

- Model: KG 12

- Capacity: 6,5 t Volumen

- Type: Melting plants, Melting plants

Mainly consists of: Steel vessel Pan traverse Planetary gearbox type: SG 182 with manual drive Ladle book Transport trolley lining 1.9 tons As seen, exw Germany

- Position: 101511

- Model: KG 10

- Capacity: 5,5 t Volumen

- Type: Melting plants, Melting plants

Mainly consists of: Steel vessel Pan traverse Planetary gearbox type: SG 182 with manual drive Ladle book Transport trolley Lining 1.5 tons As seen, ex works Germany

- Position: 101510

- Brand: ABP

- Year: 2012

- Capacity: 10,8mH; 1.500A

- Type: Various, Various

Mainly consists of: Choke construction 10.8mH Temperature regulation Connections 160 x 160mm Temperature monitoring M4-71

- Position: 101509

- Brand: Lühr

- Model: WMF

- Year: 2007

- Capacity: Ventilator 400kW; 380V

- Type: Dedusting, Dedusting

Technical data: Total electrical power: 670 kW Filter bags: 2262 pcs. Centrifugal fan power: 400 kW Chimney and control cabinet with Siemens S-7 control and ABB frequency converter. Particle type: furan sand; soot; smoke, metal

- Position: 101508

- Brand: Kraft-Hausherr

- Model: G/HW Nr. 623

- Year: 1979/2014

- Capacity: max. 90 t

- Type: Various, Various

Annealing furnace (gas heated) with roll-off system Usable stove load: (LxW)10,2 x 3,56 m Vertikal door opening: Height 3,1m from top edge Stove wagon, width 4,2m Batch weight max. 90 tons + 23 tons of

- Position: 101507

- Brand: WEBAC

- Model: ZUFS 200x2750

- Year: 2007

- Capacity: 60/40 t/h

- Type: Sand plants, Sand plants

Mainly consists of: Unpacking group Regeneration group A Regeneration group B Shakeout cabin Dimension (LxWxH): 10x10x6,5m knock-out grates (2 pcs.) Concrete Counter-vibrating mass (2 pcs.) Funnels (2 pcs.) Vibratory conveyor troughs (4 pieces) Upper belt

- Position: 101506

- Brand: FAT

- Year: 2014

- Capacity: 20 t/h

- Type: Moulding shops, Moulding shops

Mainly consists of: Heating cooling unit marke FAT without Furan sand mixer 20 t/h double joint Radius: 1,750 mm + 3,500 = total 5,250mm 29 pcs. roller conveyors Vibration table 2 pcs. belt conveyors Cranes:

- Position: 101483

- Brand: Küttner

- Year: 2007

- Type: Sand plants, Sand plants

Mainly consists of: 2 pcs. Shake-out, dim. 3500 x 6500 mm; max. weights of 45 t = combined a large shake-out, dim.7000 x 6500 mm; max weights 75 t. 1 pc. Additional emptying station (3,5×6

- Position: 101451

- Brand: RUMP

- Model: CAPSOR 40 13-U-S

- Year: 2016

- Capacity: 246 kW

- Type: Fettling shops, Fettling shops

Mainly consists of: Hanger type Shotblaster: Blasting chamber – internal dimensions LxWxH: 6 x 5 x 7.5 m, grape dimensions: diameter – 4 m x height 6 m, hook height: 7,05 m Floor grids Bucket

- Position: 101412

- Brand: ABP

- Model: LFR 30

- Year: 2017

- Capacity: 1.000 kW

- Type: Melting plants, Melting plants

Furnace body holding cap. 45 t gross / 30 t net Mainly consists of: Furnace body with inductor and tilting chair with hydr. cylinder Hydraulic unit with control desk Three-phase-oil-stepdown-transformer 1250 kVA, 20.000 +/- 5

- Position: 101380

- Brand: Roeperwerk

- Model: H80

- Year: unknown

- Capacity: 80 Liter shooting volume

- Type: Core shops, Core shops

Mainly consists of: Core shooter H80 Max. core box dimensions: (Horizontal) LxBxH 1000x720x800 mm Roller conveyor for core box without housing Electrical control panel modernised with new Siemens S7 PLC controls and Visual display Lüber

- Position: 101189

- Brand: ASEA / ABB

- Model: LRI 5

- Capacity: 500 kW

- Type: Melting plants, Melting plants

Technical data: – frequency: 50 Hz – rated voltage: 530 V – rated current: 1720 A – nominal temperature: 1500°C

- Position: 101179

- Brand: Lüber

- Model: UCM300

- Year: 1994/2016

- Capacity: 6 t/h

- Type: Core shops, Core shops

Complete automatic core sand preparation & distribution plant for charging to serveral core shooters Mainly consists of: Primary machine Mixer UCM 300kg mobil Sand dosing system Sand day silo Resin day silo with heating Hardener

How it works

On this page you will find a variety of used foundry equipment for sale. In our stock list you will find plants from the areas of moulding, sand plants, core making, cleaning, conveyor, measuring technology and dedusting.

The purchase of used foundry equipment is often an economically interesting alternative of buying a new plant.

Benefit from our specialist know-how – We accompany our customers from professional advice, recording customer needs, procurement of the required plants, sales and monitoring of the entire project up to the reconstruction of the acquired plant.

We offer you a comprehensive all-round service – once the right system has been found, we will of course also take care of its dismantling, packaging and loading in containers or on trucks as well as all customs and shipping matters. We can respond flexibly to all customer requests.

If necessary and possible, we also offer overhaul, modernization, upgrading etc. in our factory and cold start of the plant before shipping.

With every step and every task, our customers can rely on our great professional competence and experience, which we have been able to continuously optimize through decades of services in the industry.

Our strengths in the trade of used foundry equipment at a glance:

- Longterm experience in all areas of iron and non-iron foundries

- Extensive know-how in the field of technology, sales and marketing of used foundry plants from well-known manufacturers (such as DISA, Sinto, Laempe, Eirich, Webac, ABP, Inductotherm and Junker)

- Close cooperation with the manufacturers

- Large network of international partners and industry representatives

We are also your partner when it comes to moving existing facilities (foundry relocation) or services relating to your existing facility.

Did you know that we send out two to three newsletters a month to inform you about our new additions to used foundry equipment? If you no longer want to do without one of our offers, please subscribe to our newsletter.

Please do not hesitate to contact us if you find a suitable system in our stock list.